Nickel 200 Ball Valve

Nickel 200 Ball Valve

Nickel 200 Plug Valve

Nickel 200 Plug Valve

Nickel 200 ANSI Gate Valve

Nickel 200 ANSI Gate Valve

Nickel 200 Gate Valve

Nickel 200 Gate Valve

Nickel 200 ANSI Globe Valve

Nickel 200 ANSI Globe Valve

Nickel 200 Globe Valve

Nickel 200 Globe Valve

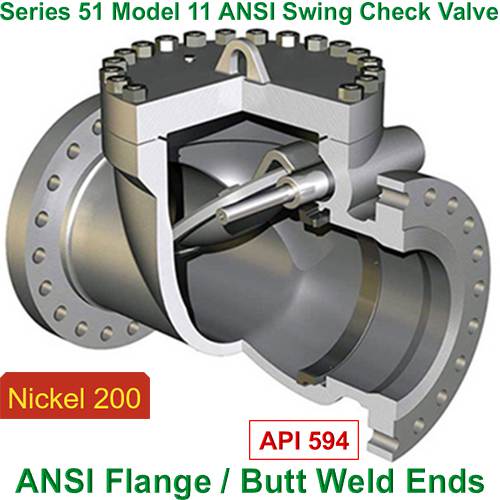

Nickel 200 ANSI Check Valve

Nickel 200 ANSI Check Valve

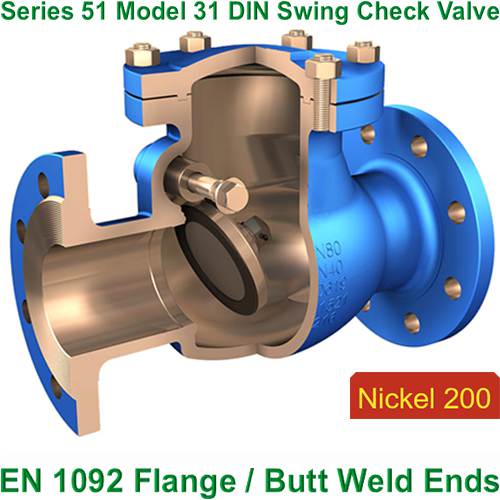

Nickel 200 DIN Check Valve

Nickel 200 DIN Check Valve

Nickel 200 Butterfly Valve

Nickel 200 Butterfly Valve

Nickel 200 ANSI Y Type Strainer

Nickel 200 ANSI Y Type Strainer

Nickel 200 DIN Y Type Strainer

Nickel 200 DIN Y Type Strainer

Nickel 200 Safety Valve

Nickel 200 Safety Valve

Series 33 Model 01 200

Series 33 Model 01 200

Series 33 Model 51 200

Series 33 Model 51 200

Series 43 Model 01 200

Series 43 Model 01 200

Series 43 Model 51 200

Series 43 Model 51 200

Series 59 Model 01 200

Series 59 Model 01 200

Series 59 Model 51 200

Series 59 Model 51 200

Freeman Valve's Nickel 200 valve offers the following advantages:

1.1 Excellent Corrosion Resistance:

a. Freeman Valve's Nickel 200 valves offer excellent resistance to reducing acids (such as hydrochloric acid and sulfuric acid), alkaline solutions, and saline media.

b. Freeman Valve's Nickel 200 valves are stable in dry halogens (such as chlorine and fluorine) and high-temperature, non-oxidizing environments.

1.2 Excellent Mechanical Properties:

Freeman Valve's Nickel 200 valves maintain strength and ductility at low to medium temperatures (-250°C to +300°C).

1.3 High Purity:

Freeman Valve's Nickel 200 valves have a nickel content of ≥99.0% and are low in impurities, making them suitable for applications requiring high cleanliness (such as the food and nuclear industries).

2. When using Nickel 200 valves, please note the following:

2.1 High-temperature limitations: Nickel 200 valves will become embrittled due to grain boundary graphitization when used for extended periods above 315°C (requiring the use of low-carbon nickel such as Nickel 201).

2.2 Nickel 200 valves are sensitive to oxidizing media and are not resistant to strong oxidizing acids such as nitric acid and concentrated sulfuric acid.

3 Conclusion:

3.1 The core value of Nickel 200 valves lies in their purity and basic corrosion resistance, making them suitable for non-extremely oxidizing/high-temperature corrosive environments.

3.2 The core value of Nickel 200 valves in the chemical industry lies in the "reducing media + high purity requirements" scenario, making them a benchmark material for handling caustic soda, fluorides, and organic acids.

4. Typical Applications of Freeman Valve's Nickel 200 Valves:

4.1 Freeman Valve's Nickel 200 valves are widely used in caustic soda (NaOH/KOH) production and processing, such as in evaporators, molten caustic soda transfer piping, and reactor linings. In high-temperature, high-concentration caustic solutions (≤50% NaOH, ≤300°C), Nickel 200 valves offer excellent corrosion resistance, preventing stress corrosion cracking (compared to stainless steel).

4.2 Freeman Valve's Nickel 200 valves are widely used in organic chemical processing (fatty acid and phenol production), such as in reactors, distillation columns, and condensers. Nickel 200 valves are resistant to organic acids (such as acetic acid and oleic acid) and organic solvents, ensuring purity and preventing product contamination.

4.3 Freeman Valve's Nickel 200 valves are widely used in the chlor-alkali industry, including equipment such as chlorine drying towers, brine heaters, and electrode assemblies. Nickel 200 valves are resistant to corrosion from wet chlorine, hypochlorite, and high-temperature salt water (oxidizing acids should be avoided).

4.4 Freeman Valve's Nickel 200 valves are widely used in hydrofluoric acid (HF) and fluoride processing applications, such as HF storage tanks, fluorination reactors, and pickling equipment. Nickel 200 valves are extremely resistant to fluoride ion corrosion (superior to most stainless steels).

4.5 Freeman Valve's Nickel 200 valves are widely used in sulfuric and hydrochloric acid environments (non-oxidizing conditions), such as dilute sulfuric acid (<60%) storage tanks, hydrochloric acid heat exchangers, and acid pump components. However, Nickel 200 valves are not suitable for concentrated sulfuric acid (>70%) or mixed acids containing oxidants (such as HNO₃).

4.6 Freeman Valve's Nickel 200 valves are widely used in salt solution processing applications, such as ammonium chloride and nickel sulfate crystallization equipment, and salt dryers. Nickel 200 valves are resistant to halide stress corrosion, but pitting corrosion should be avoided.