Monel 400 Ball Valve

Monel 400 Ball Valve

Monel 400 Ball Valve

Monel 400 Ball Valve

Monel 400 Ball Valve

Monel 400 Ball Valve

Monel 400 Ball Valve Multi Way

Monel 400 Ball Valve Multi Way

Monel 400 Plug Valve

Monel 400 Plug Valve

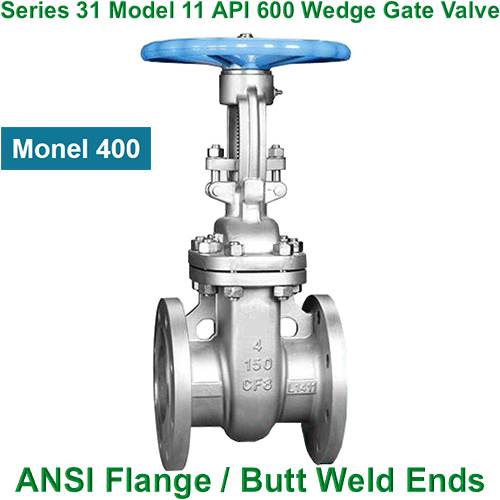

Monel 400 Gate Valve

Monel 400 Gate Valve

Monel 400 Gate Valve

Monel 400 Gate Valve

Monel 400 Gate Valve

Monel 400 Gate Valve

Monel 400 Gate Valve

Monel 400 Gate Valve

Monel 400 Globe Valve

Monel 400 Globe Valve

Monel 400 Globe Valve

Monel 400 Globe Valve

Monel 400 Globe Valve

Monel 400 Globe Valve

Monel 400 Globe Valve

Monel 400 Globe Valve

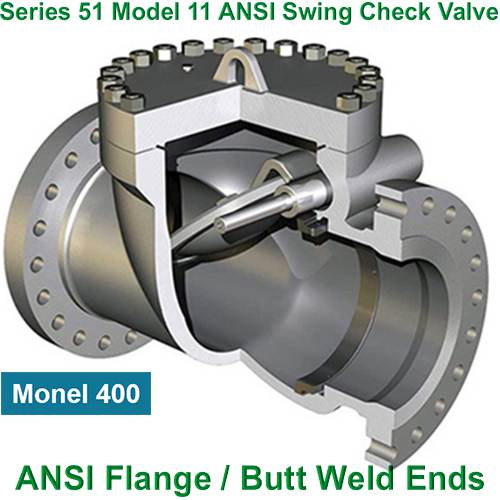

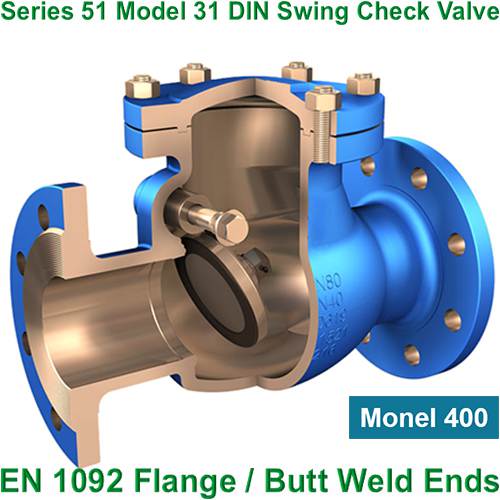

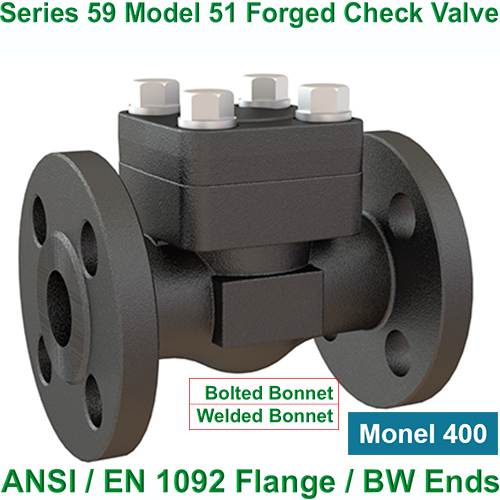

Monel 400 Check Valve

Monel 400 Check Valve

Monel 400 Check Valve

Monel 400 Check Valve

Monel 400 Check Valve

Monel 400 Check Valve

Monel 400 Check Valve

Monel 400 Check Valve

Monel 400 Butterfly Valve

Monel 400 Butterfly Valve

Monel 400 Y Type Strainer

Monel 400 Y Type Strainer

Monel 400 Y Type Strainer

Monel 400 Y Type Strainer

Monel 400 Safety Valve

Monel 400 Safety Valve

1. Freeman Valve's Monel 400 valves offer the following advantages:

1.1 Excellent Corrosion Resistance:

a. Freeman Valve's Monel 400 valves are resistant to seawater, salt spray, hydrofluoric acid, sulfuric acid, alkaline solutions, and are particularly resistant to reducing media, surpassing stainless steel.

b. Freeman Valve's Monel 400 valves are highly resistant to chloride stress corrosion cracking (SCC) and are suitable for use in environments containing chloride ions (such as desalination).

1.2 Excellent Mechanical Properties:

a. Freeman Valve's Monel 400 valves feature high strength, excellent toughness, and high ductility (maintaining performance even at low temperatures).

b. Freeman Valve's Monel 400 valves are suitable for a wide operating temperature range (-200°C to +600°C).

1.3 Resistance to Abrasion and Erosion Corrosion:

Freeman Valve's Monel 400 valves are ideal for high-velocity fluids or media containing particles.

2. When using Monel 400 valves, please note the following:

Monel 400 valves are not resistant to oxidizing acids and corrode rapidly in strong oxidizing media such as nitric acid and concentrated sulfuric acid.

3. Typical applications of Freeman Valve's Monel 400 valves:

3.1 Freeman Valve's Monel 400 valves are widely used in marine and seawater systems. For example, seawater heat exchangers and other equipment resistant to seawater corrosion.

3.2 Freeman Valve's Monel 400 valves are widely used in hydrofluoric acid (HF) equipment, such as HF storage tanks and pipelines (Monel is one of the few metal materials resistant to HF).

3.3 Freeman Valve's Monel 400 valves are widely used in oil and gas equipment, such as downhole equipment (resistant to H₂S and CO₂ corrosion).

3.4 Freeman Valve's Monel 400 valves are widely used in chemical process equipment. Examples include sulfuric acid/hydrochloric acid reactors, distillation towers, and condensers (for low- to medium-concentration, non-oxidizing environments).

3.5 Freeman Valve's Monel 400 valves are widely used in bleaching equipment in the paper industry and in hot salt systems (such as molten salt reactors).

Corrosion Resistance Analysis of Freeman Valve's Monel 400 Valves in Seawater Environments

Monel 400 (UNS N04400) is a nickel-copper alloy (~67% Ni, ~30% Cu). Due to its excellent seawater corrosion resistance, it is widely used in marine engineering, shipbuilding, and desalination. However, it does have limitations under certain conditions. The following details its advantages and disadvantages.

1. Advantages of Monel 400 Valves in Seawater Corrosion

1.1 Excellent Uniform Corrosion Resistance:

1.1.1 High Seawater Corrosion Resistance (High Cl⁻ Environment):

a. Freeman Valve's Monel 400 valves exhibit an extremely low corrosion rate (typically <0.025 mm/year) in ambient seawater (pH 7.5-8.4), surpassing 304/316 stainless steel (which is prone to pitting corrosion).

b. Freeman Valve's Monel 400 valves are resistant to salt spray corrosion and are suitable for use in marine atmospheric environments (such as offshore platforms and ship deck equipment).

1.1.2 Resistance to Flowing Seawater Erosion Corrosion:

Freeman Valve's Monel 400 valves have a high nickel content, giving them excellent resistance to erosion corrosion, making them suitable for high-velocity fluid environments such as seawater pumps, propellers, and valves.

1.2 Resistance to Chloride Ion Stress Corrosion Cracking (Cl-SCC):

Due to their high nickel content, Freeman Valve's Monel 400 valves are less susceptible to stress corrosion cracking (SCC), making them ideal for applications such as seawater piping systems and heat exchangers (especially those operating in high-temperature seawater conditions).

1.3 Resistance to Biofouling and Microbiologically Influenced Corrosion (MIC):

Freeman Valve's Monel 400 valves have a copper content of up to 30%, which imparts certain antibacterial properties. This effectively reduces the adhesion of marine organisms such as barnacles and algae, thereby reducing the risk of MIC.

1.4 Excellent Low-Temperature Performance:

Freeman Valve's Monel 400 valves maintain their toughness in extremely cold seawater and exhibit no tendency to embrittlement, making them ideal for low-temperature marine equipment.

2 Corrosion Limitations of Monel 400 Valves in Seawater

2.1 Monel 400 Valves Are Sensitive to Abrasion in High-Velocity and Sandy Seawater:

Although Monel 400 valves are resistant to erosion corrosion, if the seawater contains suspended sand (such as in near-shore waters), prolonged high flow rates may lead to increased wear (requiring the use of a wear-resistant coating).

2.2 Monel 400 Valves' Susceptibility to Localized Corrosion (Pitting and Crevice Corrosion):

a. Pitting: Monel 400 valves may experience mild pitting corrosion (but much less than stainless steel) in stagnant seawater or low-oxygen environments (such as dead ends in pipelines). However, this can be mitigated by increasing the flow rate or using cathodic protection (e.g., sacrificial anodes).

b. Crevice Corrosion: Monel 400 valves may experience corrosion at joints and in gasket crevices due to oxygen concentration gradients (design optimization is required to avoid crevices).

2.3 Sulfide (H₂S) Sensitivity:

Monel 400 valves in anaerobic seawater (such as in seabed mud areas) may be susceptible to H₂S production by sulfate-reducing bacteria (SRB), leading to sulfide stress corrosion (SSCC) of Monel 400 valves. However, cathodic protection (e.g., zinc anodes) can mitigate this.

3 Conclusion

Monel 400 valves are alloy valves with excellent corrosion resistance in seawater environments. They are particularly suitable for flowing seawater, high-temperature seawater, and SCC-resistant environments. However, in applications with high wear, H₂S environments, or budget constraints, alternatives (e.g., titanium alloys and super duplex steels) should be evaluated.