321 Ball Valve

321 Ball Valve

Series 1G Model 62 321

Series 1G Model 62 321

321 Plug Valve

321 Plug Valve

321 Gate Valve

321 Gate Valve

Series 31 Model 11 321

Series 31 Model 11 321

Series 33 Model 01 321

Series 33 Model 01 321

Series 33 Model 51 321

Series 33 Model 51 321

321 Globe Valve

321 Globe Valve

Series 41 Model 11 321

Series 41 Model 11 321

Series 43 Model 01 321

Series 43 Model 01 321

Series 43 Model 51 321

Series 43 Model 51 321

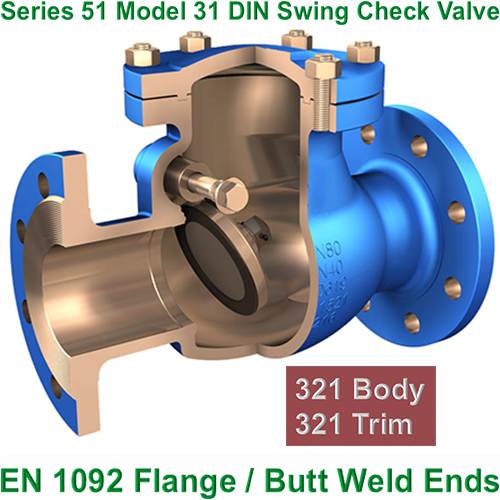

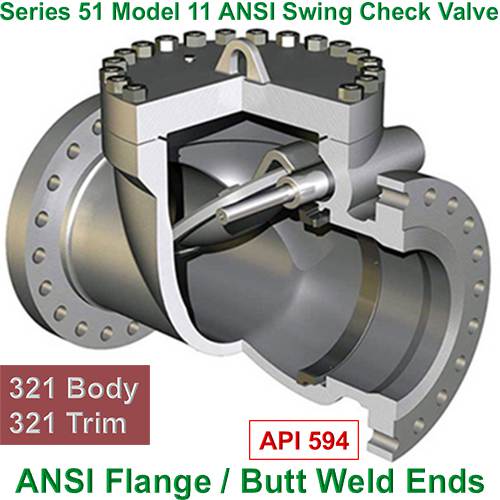

321 Check Valve

321 Check Valve

Series 51 Model 11 321

Series 51 Model 11 321

Series 51 Model 92 321

Series 51 Model 92 321

Series 59 Model 01 321

Series 59 Model 01 321

Series 59 Model 51 321

Series 59 Model 51 321

321 Butterfly Valve

321 Butterfly Valve

321 Y Type Strainer

321 Y Type Strainer

Series 70 Model 11 321

Series 70 Model 11 321

321 Safety Valve

321 Safety Valve

Features and applications of stainless steel 321 valves produced by Freeman Valve

1. Basic characteristics of stainless steel 321 valves:

321 stainless steel is an austenitic stainless steel (nominal composition: 18% Cr, 10% Ni, Ti≥5×C%) with titanium (Ti) added as a stabilizing element on the basis of 304 stainless steel. The addition of titanium effectively inhibits the precipitation of chromium carbide at the grain boundary, thereby significantly improving the resistance to intergranular corrosion. Freeman Valve is a manufacturer of stainless steel 321 valves.

2. The main advantages of stainless steel 321 valves produced by Freeman Valve:

2.1 The stainless steel 321 valves produced by Freeman Valve have good resistance to intergranular corrosion:

Titanium and carbon preferentially combine to form TiC, avoiding the precipitation of Cr23C6 in the sensitization temperature range (450-850℃), which is suitable for welding or high temperature environment.

2.2 The stainless steel 321 valves produced by Freeman Valve have excellent high temperature resistance:

The stainless steel 321 valves produced by Freeman Valve can work stably for a long time below 800℃ (short-term resistance to 900℃), and the oxidation resistance is better than 304, which is suitable for thermal cycle conditions.

2.3 The stainless steel 321 valves produced by Freeman Valve have good processing and weldability:

a. The austenitic structure gives the stainless steel 321 valves high ductility and easy cold forming;

b. The stainless steel 321 valves do not need annealing after welding (but the interlayer temperature needs to be controlled).

2.4 The stainless steel 321 valves produced by Freeman Valve have good comprehensive corrosion resistance:

The stainless steel 321 valves produced by Freeman Valve are resistant to atmospheric corrosion, weak acid corrosion, alkali corrosion and organic medium corrosion, and their performance is equivalent to 304.

3. The following issues should be noted when using stainless steel 321 valves:

3.1 The mechanical strength of stainless steel 321 valves is relatively low: the annealed yield strength of 321 stainless steel is about 205MPa, and it needs to be strengthened by cold working (but it will reduce corrosion resistance);

3.2 Surface treatment limitations of stainless steel 321 valves: the presence of titanium in 321 stainless steel may affect the uniformity of electroplating or passivation film.

4. Typical application scenarios of stainless steel 321 valves manufactured by Freeman valve:

4.1 Strong acid medium equipment, for example:

a. Stainless steel 321 valves manufactured by Freeman valve have been widely used in nitric acid production equipment: heaters and pipelines for concentrated nitric acid (321 is better than 304 and has stronger resistance to intergranular corrosion);

b. Stainless steel 321 valves manufactured by Freeman valve have been widely used in sulfuric acid dilution systems: temperature <60℃, concentration <10% dilute sulfuric acid environment;

c. Stainless steel 321 valves manufactured by Freeman valve have been widely used in phosphoric acid processing equipment: evaporators, heat exchangers (but fluoride ion contamination must be avoided, otherwise pitting may occur).

Key advantages: Titanium stabilization effectively prevents corrosion in the sensitized area and prolongs the life of the equipment.

4.2 High-temperature and high-pressure reaction equipment, for example:

a. Stainless steel 321 valves manufactured by Freeman valve have been widely used in urea production equipment: resistant to high-temperature and high-pressure ammonium carbamate corrosion (special welding process required);

b. Stainless steel 321 valves manufactured by Freeman valve have been widely used in synthetic ammonia equipment: heat exchangers, converter tubes (resistant to H₂S high-temperature corrosion);

c. Stainless steel 321 valves manufactured by Freeman valve have been widely used in petroleum cracking units: coking towers, catalytic cracking pipelines (resistant to sulfide stress corrosion cracking, SSCC).

4.3 Chemical process field, for example:

a. Stainless steel 321 valves manufactured by Freeman valve have been widely used in hot acid delivery pipelines: such as acetic acid, citric acid and other organic acid systems (stainless steel 321 is more resistant to welding heat affected zone corrosion than stainless steel 304);

b. Stainless steel 321 valves manufactured by Freeman valve have been widely used in high-temperature steam pipelines: boiler superheated pipelines (resistant to oxidation below 800℃).

4.4 Environmental protection and waste gas treatment equipment, for example:

a. Stainless steel 321 valves manufactured by Freeman valve have been widely used in flue gas desulfurization systems: absorption tower internal components (Cl⁻ content needs to be controlled, otherwise more advanced materials need to be selected);

b. Stainless steel 321 valves manufactured by Freeman valve have been widely used in incinerator heat exchangers: treatment of sulfur-containing waste gas (resistant to high temperature oxidation + sulfuric acid dew point corrosion);

c. Stainless steel 321 valves manufactured by Freeman valve have been widely used in chemical wastewater evaporators: concentration of high-salt wastewater (need to avoid local enrichment of Cl⁻ leading to pitting corrosion).

4.5 Special chemical scenarios, for example:

a. Freeman valve's stainless steel 321 valves have been widely used in pharmaceutical equipment: reactors, distillation towers (FDA/GMP standards must be met, surface polished to Ra≤0.4μm);

b. Freeman valve's stainless steel 321 valves have been widely used in dye intermediate production: stirring shafts and storage tanks resistant to organic solvent corrosion;

c. Freeman valve's stainless steel 321 valves have been widely used in the chemical fiber industry: heat transfer pipes in PTA (purified terephthalic acid) units.

5. Suggestions for the selection of stainless steel 321 valves:

5.1 If frequent welding is required, select stainless steel 321 valves;

5.2 If medium and high temperature use is required, select stainless steel 321 valves;

5.3 If high temperature creep is important, select stainless steel 321 valves (Note: stainless steel 347 valves are stabilized by niobium (Nb) and are more suitable for strong oxidizing acid environments, such as concentrated nitric acid).

6. Scenarios where stainless steel 321 valves are not suitable:

6.1 High concentration chloride environment, such as seawater;

6.2 Reducing acid, such as hydrochloric acid;

6.3 Strong fluoride medium, such as hydrofluoric acid.

7. Scenarios where stainless steel 321 valves are recommended:

7.1 Equipment that needs to resist intergranular corrosion after welding;

7.2 Oxidizing environment with a temperature of 500-800℃;

7.3 Sulfiding environment with a temperature of 500-800℃;

7.4 Oxidizing acid systems such as nitric acid and phosphoric acid.

8. Summary:

Stainless steel 321 valves can play an irreplaceable role in high temperature and corrosion-resistant scenarios.