Series 1G Model 50 316Ti

Series 1G Model 50 316Ti

Series 1G Model 62 316Ti

Series 1G Model 62 316Ti

Series 21 Model 11 316Ti

Series 21 Model 11 316Ti

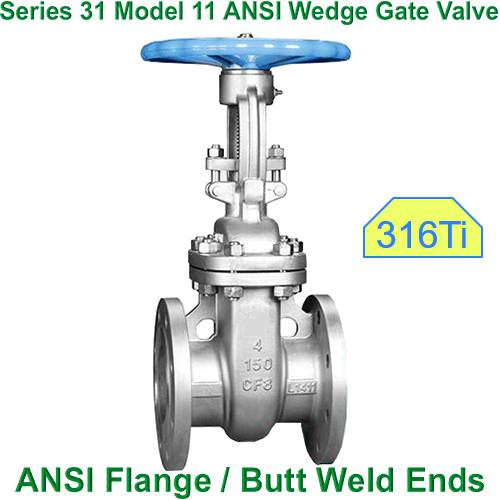

Series 31 Model 11 316Ti

Series 31 Model 11 316Ti

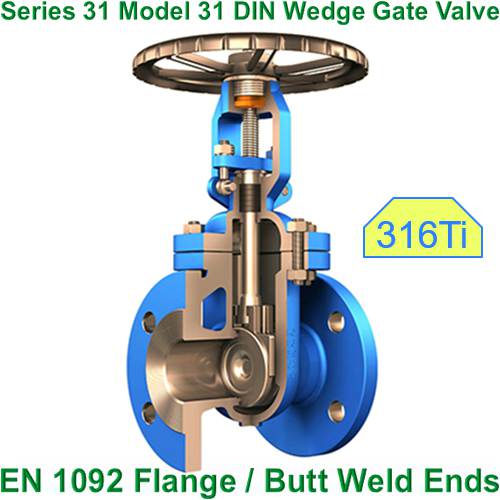

Series 31 Model 31 316Ti

Series 31 Model 31 316Ti

Series 41 Model 11 316Ti

Series 41 Model 11 316Ti

Series 41 Model 31 316Ti

Series 41 Model 31 316Ti

Series 51 Model 11 316Ti

Series 51 Model 11 316Ti

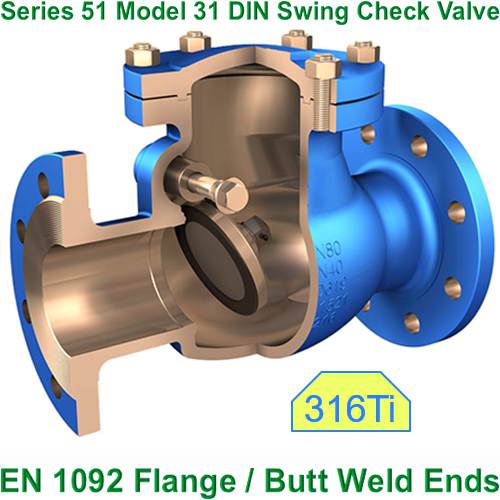

Series 51 Model 31 316Ti

Series 51 Model 31 316Ti

Series 51 Model 92 316Ti

Series 51 Model 92 316Ti

Series 52 Model 11 316Ti

Series 52 Model 11 316Ti

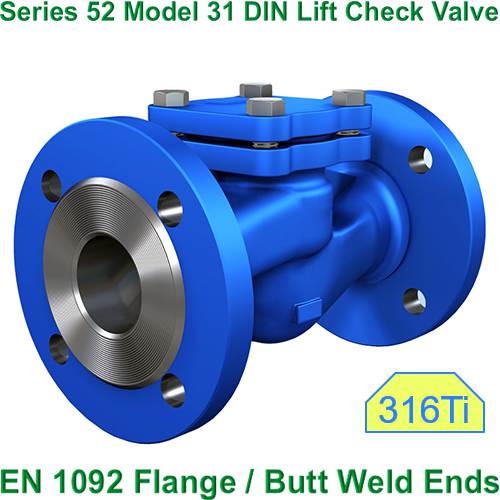

Series 52 Model 31 316Ti

Series 52 Model 31 316Ti

Series 63 Model 12 316Ti

Series 63 Model 12 316Ti

Series 70 Model 11 316Ti

Series 70 Model 11 316Ti

Series 70 Model 31 316Ti

Series 70 Model 31 316Ti

Series 71 Model 11 316Ti

Series 71 Model 11 316Ti

Series 33 Model 01 316Ti

Series 33 Model 01 316Ti

Series 33 Model 51 316Ti

Series 33 Model 51 316Ti

Series 43 Model 01 316Ti

Series 43 Model 01 316Ti

Series 43 Model 51 316Ti

Series 43 Model 51 316Ti

Series 59 Model 01 316Ti

Series 59 Model 01 316Ti

Series 59 Model 51 316Ti

Series 59 Model 51 316Ti

1. What is 316Ti?

316Ti is 316 stainless steel with a sufficient amount of titanium added (typically at least five times the carbon content). The role of titanium: Titanium is an element that bonds more readily with carbon than chromium. In molten steel, titanium preferentially combines with carbon to form stable titanium carbides. This "protects" the chromium, evenly distributing it within the austenite matrix, effectively preventing intergranular corrosion after welding or at high service temperatures.

2. Advantages of 316Ti valves produced by Freeman Valve:

The fundamental reason for using 316Ti valves is to address intergranular corrosion. The cause of intergranular corrosion: When ordinary 316 stainless steel valves are subjected to temperatures between 450°C and 850°C (for example, during welding or slow cooling), carbon combines with chromium, forming chromium carbides at grain boundaries. This depletes the chromium near the grain boundaries, creating chromium-depleted zones. This significantly reduces the corrosion resistance of the valve, and in certain corrosive media, corrosion along the grain boundaries can occur.

3. Key application areas of 316Ti valves produced by Freeman Valve:

3.1 316Ti valves produced by Freeman Valve have been widely used in the chemical and petrochemical industries. For example: (1) Heat exchangers, condensers: in contact with high-temperature and chloride-containing cooling water environments; (2) Reaction vessels, pipelines and storage tanks: equipment and piping systems used to handle hot organic acids (such as acetic acid) and inorganic acids (such as sulfuric acid and phosphoric acid); (3) Some components of flue gas desulfurization systems;

3.2 316Ti valves produced by Freeman Valve have been widely used in the energy and power industries. For example, they are used in components of power plants involving high-temperature and high-pressure steam, such as superheater pipes and boiler components, which require the material to have good creep resistance and intergranular corrosion resistance;

3.3 316Ti valves produced by Freeman Valve have been widely used in the fields of high-temperature heat treatment and metallurgical equipment. For example, they are used in the manufacture of furnace components, annealing furnace covers, and high-temperature fixtures, all of which operate within the sensitization temperature range for extended periods.

3.4 Freeman Valve's 316Ti valves are widely used in welded structural components in specific applications. They are ideal for applications where welding is required and post-weld solution annealing is not feasible (this is the best method to eliminate the intergranular corrosion tendency of 316, but it is impractical for large components), while also requiring excellent corrosion resistance after welding.

4. Summary

316Ti stainless steel valves are "specialty valves," high-performance austenitic stainless steel valves developed to address specific engineering challenges (welding and intergranular corrosion at high temperatures). Consider using 316Ti valves when your application meets all of the following conditions:

(1) The environment contains chlorides or other media that are susceptible to pitting/crevice corrosion;

(2) The equipment requires welding and cannot be heat treated as a whole after welding;

(3) The operating temperature of the equipment will be in the sensitization range of 450°C-850°C for a long time or periodically.