UNS S38815 Ball Valve, 310M Ball Valve

UNS S38815 Ball Valve, 310M Ball Valve

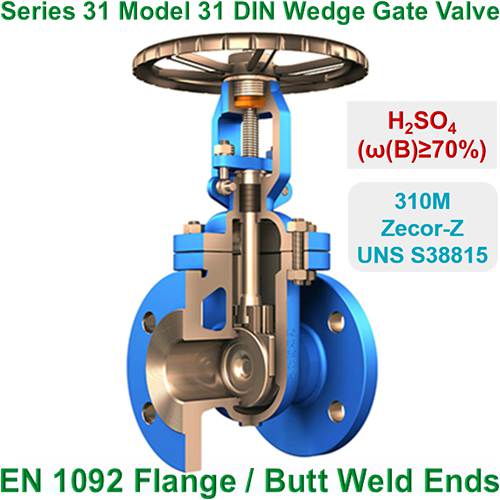

UNS S38815 Gate Valve, 310M Gate Valve

UNS S38815 Gate Valve, 310M Gate Valve

UNS S38815 Globe Valve, 310M Globe Valve

UNS S38815 Globe Valve, 310M Globe Valve

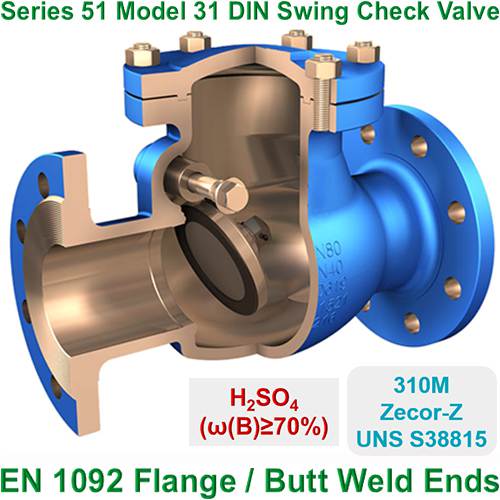

UNS S38815 Check Valve, 310M Check Valve

UNS S38815 Check Valve, 310M Check Valve

UNS S38815 Gate Valve, 310M Gate Valve

UNS S38815 Gate Valve, 310M Gate Valve

UNS S38815 Globe Valve, 310M Globe Valve

UNS S38815 Globe Valve, 310M Globe Valve

UNS S38815 Check Valve, 310M Check Valve

UNS S38815 Check Valve, 310M Check Valve

UNS S38815, also known as Zecor-Z or 310M, is a duplex stainless steel Valve that combines a dual-phase structure of austenite and ferrite, offering a unique balance of properties. Freeman Valve's UNS S38815 valves offer the following advantages:

1.1 Excellent Corrosion Resistance:

① Freeman Valve's UNS S38815 valves significantly outperform 304/316 austenitic stainless steels in chloride environments (such as seawater and saltwater) in pitting and crevice corrosion resistance.

② Freeman Valve's UNS S38815 valves significantly outperform ordinary austenitic stainless steels in stress corrosion cracking (SCC).

③ Freeman Valve's UNS S38815 valves exhibit excellent resistance to media such as dilute sulfuric acid and organic acids.

1.2 Fatigue and Wear Resistance:

The presence of ferrite in Freeman Valve's UNS S38815 valves enhances wear resistance, making them suitable for dynamic load environments.

2. When using UNS S38815 valves, please note the following:

2.1 UNS S38815 valves have limited low-temperature toughness: The ferrite phase may become brittle at extremely low temperatures, making them unsuitable for ultra-low-temperature environments such as liquid nitrogen (austenitic stainless steel is preferred).

2.2 UNS S38815 valves are sensitive to heat treatment: Prolonged heating at 300-900°C may cause precipitation of sigma phase or carbides, resulting in brittleness or decreased corrosion resistance. Strict control of the heat treatment process is required.

2.3 UNS S38815 valve application temperature limit: Long-term operating temperatures generally do not exceed 250-300°C. Phase transformation may occur at high temperatures.

2.4 UNS S38815 valves should avoid use in environments with strong reducing acids (such as hydrochloric acid).

3 Key Application Areas for Freeman Valve's UNS S38815 Valves:

3.1 Freeman Valve's UNS S38815 valves are widely used in the oil and gas industry, for example, in chloride-resistant systems such as submarine pipelines and downhole equipment operating in acidic environments (including H₂S/CO₂).

3.2 Freeman Valve's UNS S38815 valves are widely used in the chemical and petrochemical industries, for example, in reactors, heat exchangers, storage tanks (especially those containing chloride ions or acidic media), and in chemical equipment such as sulfuric acid and phosphoric acid.

3.3 Freeman Valve's UNS S38815 valves are widely used in seawater treatment, for example, in desalination plants, condensers, and seawater pumps.

3.4 Freeman Valve's UNS S38815 valves are widely used in the pulp and paper industry, for example, in high-chloride environment equipment in bleaching plants.

3.5 Freeman Valve's UNS S38815 valves have been widely used in the energy and environmental protection sectors, such as flue gas desulfurization (FGD) systems and wastewater treatment equipment.

4 Conclusion:

UNS S38815 valves are suitable for moderately harsh environments requiring a balance of strength, corrosion resistance, and cost, and perform particularly well in the presence of chloride ions.

Analysis of the Advantages and Disadvantages of Freeman Valve's UNS S38815 Valves in Concentrated Sulfuric Acid Corrosion

1 Advantages of the UNS S38815 Valves in Concentrated Sulfuric Acid Corrosion:

1.1 Resistance of the UNS S38815 Valves in Moderately Concentrated Sulfuric Acid (80%-95%): In concentrated sulfuric acid (above 90%) at room temperature or slightly elevated temperatures (<50°C), a passive film forms on the surface of the UNS S38815 valve, exhibiting excellent corrosion resistance. Furthermore, the balanced duplex structure (austenite + ferrite) of the UNS S38815 valves provides strong resistance to uniform corrosion.

1.2 Stability of the UNS S38815 Valves in Oxidizing Environments: If the concentrated sulfuric acid contains oxidizing impurities (such as dissolved oxygen, Fe₃⁺, Cu₂⁺, etc.), the passivation ability of the UNS S38815 valves is enhanced, further reducing the corrosion rate.

1.3 Freeman Valve's UNS S38815 valves are resistant to stress corrosion cracking (SCC). In sulfuric acid environments containing trace amounts of chloride ions (such as industrial sulfuric acid), UNS S38815 valves exhibit significantly better SCC resistance than austenitic stainless steels (such as 316L).

2 Disadvantages of UNS S38815 valves in their corrosion resistance to concentrated sulfuric acid:

2.1 High corrosion risk for UNS S38815 valves in reducing concentrated sulfuric acid: At high temperatures (>50°C) or in reducing concentrated sulfuric acid (such as low-purity sulfuric acid containing H₂S, SO₂, etc.), the passive film on UNS S38815 valves is easily destroyed, causing a sharp increase in corrosion rate. Furthermore, the ferrite phase may corrode preferentially, leading to localized pitting or selective dissolution.

2.2 Limitations of UNS S38815 Valves for Low-Concentration Sulfuric Acid (<80%): Dilute sulfuric acid (especially <50%) is more corrosive to UNS S38815 valves. In these cases, higher alloy materials (such as Hastelloy C-276 or PTFE-lined equipment) are required.

2.3 Temperature Sensitivity of UNS S38815 Valves: Long-term use of UNS S38815 valves in concentrated sulfuric acid at temperatures above 60°C may cause intergranular corrosion or sigma phase precipitation, requiring strict temperature limits.

2.4 Impact of Chloride Ion Impurities on UNS S38815 Valves: Chloride ions (Cl⁻) in concentrated sulfuric acid may cause pitting and crevice corrosion, especially in stagnant areas.

Corrosion Resistance Comparison of Hastelloy C-276 Valves and UNS S38815 Valves

1 Advantages of Hastelloy C-276 Valves:

1.1 Hastelloy C-276 valves are resistant to corrosion in concentrated sulfuric acid at all concentrations: From dilute sulfuric acid (<10%) to fuming sulfuric acid (>100%), they perform excellently across a wide concentration range, particularly at high temperatures (up to the boiling point) and in reducing environments.

1.2 Hastelloy C-276 valves are resistant to localized corrosion: Hastelloy C-276 valves are virtually unaffected by pitting and crevice corrosion, even in the presence of chloride ions (Cl⁻) or in alternating redox medium.

1.3 High-temperature adaptability of Hastelloy C-276 valves: Hastelloy C-276 valves can operate at temperatures exceeding 200°C (in concentrated sulfuric acid) for extended periods without the risk of sigma-phase embrittlement.

2. Disadvantages of Hastelloy C-276 Valves:

Overdesign Risk: Performance is redundant in ambient temperature oxidizing concentrated sulfuric acid (>90%), resulting in a low cost-performance ratio.

3. Advantages of UNS S38815 Valves:

UNS S38815 Valves are resistant to medium- and high-concentration oxidizing acids: UNS S38815 valves exhibit excellent corrosion resistance in ambient temperature (~50°C) and 90%-95% concentrated sulfuric acid (containing oxidizing media such as Fe₃⁺ and Cu₂⁺), and their cost is significantly lower than C-276.

4 Disadvantages of UNS S38815 Valves: Concentration and Temperature Sensitivity:

4.1 UNS S38815 valves have a high corrosion rate in dilute sulfuric acid (<80%);

4.2 UNS S38815 valves are susceptible to damage to the passivation film in high temperatures (>60°C) or in reducing acids (containing H₂S/SO₂);

4.3 UNS S38815 valves may cause localized corrosion in media containing chloride ions.

5 Application Selection

5.1 Situations Where Hastelloy C-276 Valves are Preferred:

① High-temperature concentrated sulfuric acid (e.g., concentration processes >80°C, waste acid recovery);

② Reducing/impurity environments (industrial sulfuric acid containing H₂S, SO₂, and Cl⁻);

③ Critical equipment (e.g., reactors and heat exchangers requiring long life and zero leakage).

5.2 Preferred Situations for UNS S38815 Valves:

① Normal/low-temperature oxidizing concentrated sulfuric acid (e.g., 90%-95% sulfuric acid storage tanks and pipelines).

② Budget limitations and mild corrosion conditions (regular inspection and maintenance required).

③ Requirement of high-strength and lightweight structural components.

6 Summary

6.1 Hastelloy C-276 valves are the "ultimate solution" for concentrated sulfuric acid (especially high-temperature, reducing, and impurity-laden), but they are costly.

6.2 UNS S38815 valves are an economical option, limited to oxidizing, medium-low-temperature, and high-concentration sulfuric acid, requiring strict monitoring of environmental parameters.

Key Decision: Evaluate the sulfuric acid's purity, temperature, redox properties, and equipment life requirements, and verify through corrosion coupon testing if necessary.