347 Ball Valve

347 Ball Valve

Series 1G Model 62 347

Series 1G Model 62 347

347 Plug Valve

347 Plug Valve

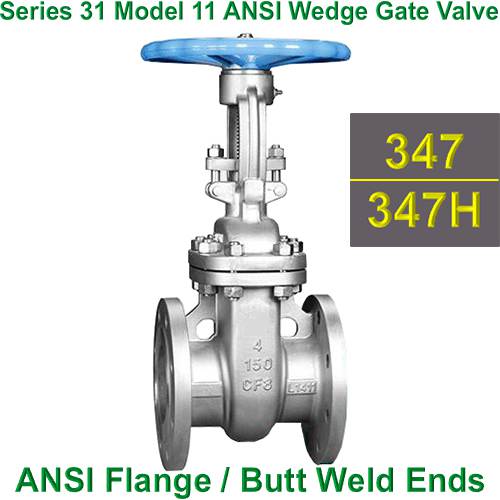

347 Gate Valve

347 Gate Valve

Series 31 Model 11 347

Series 31 Model 11 347

Series 33 Model 01 347

Series 33 Model 01 347

Series 33 Model 51 347

Series 33 Model 51 347

347 Globe Valve

347 Globe Valve

Series 41 Model 11 347

Series 41 Model 11 347

Series 43 Model 01 347

Series 43 Model 01 347

Series 43 Model 51 347

Series 43 Model 51 347

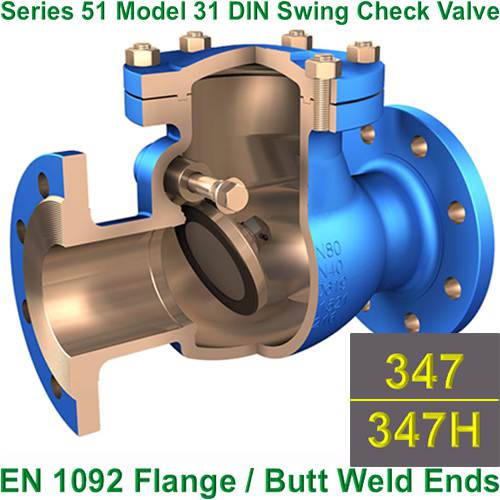

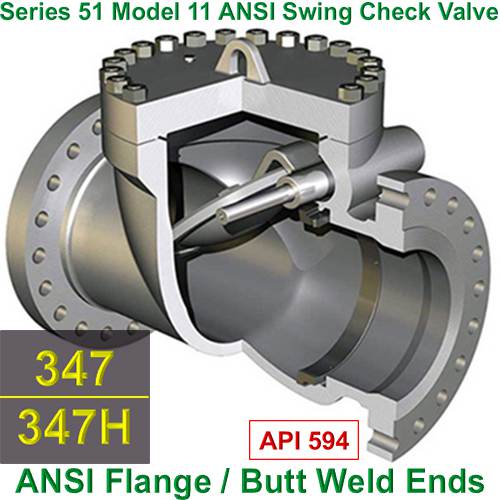

347 Check Valve

347 Check Valve

Series 51 Model 11 347

Series 51 Model 11 347

Series 51 Model 92 347

Series 51 Model 92 347

Series 59 Model 01 347

Series 59 Model 01 347

Series 59 Model 51 347

Series 59 Model 51 347

347 Butterfly Valve

347 Butterfly Valve

347 Y Type Strainer

347 Y Type Strainer

Series 70 Model 11 347

Series 70 Model 11 347

347 Safety Valve

347 Safety Valve

1. The stainless steel 347 valves produced by Freeman Valve have the following advantages:

1.1 Excellent high temperature resistance:

a. Niobium (Nb) is added as a stabilizer in the stainless steel 347 valves produced by Freeman Valve, which significantly improves the ability to resist sensitization (carbide precipitation) and is suitable for high temperature environments of 425-900℃ (such as welding or long-term heat exposure);

b. The stainless steel 347 valves produced by Freeman Valve are more resistant to high temperature creep and oxidation than 304/316;

1.2 Excellent welding performance:

The niobium element in the stainless steel 347 valves produced by Freeman Valve inhibits intergranular corrosion in the heat affected zone (HAZ) of welding, and is suitable for parts that are not heat treated after welding;

1.3 Good corrosion resistance:

a. The stainless steel 347 valves produced by Freeman Valve perform well in oxidizing acids (such as nitric acid), organic acids and weak bases, and have better resistance to intergranular corrosion than 304.

b. Freeman Valve's stainless steel 347 valves are better than 304 in resistance to chloride stress corrosion cracking, but slightly worse than 316.

1.4 Good mechanical properties:

Freeman Valve's 347 stainless steel valves have similar strength to stainless steel 304 at room temperature, but they can still maintain high strength at high temperatures.

2. The following issues should be noted when using stainless steel 347 valves:

Stainless steel 347 valves are not suitable for reducing environments: they have limited corrosion resistance in sulfur-containing or reducing acids (such as sulfuric acid) and need to be selected according to the medium.

3. Stainless steel 347H is a high-carbon version of 347 (carbon content 0.04-0.10%), optimized for high-temperature strength while retaining the niobium (Nb) stabilization properties of 347. The stainless steel 347H valves produced by Freeman Valve have the following advantages:

3.1 Excellent high temperature performance

a. The stainless steel 347H valves produced by Freeman Valve have higher high temperature strength: Due to the increased carbon content, 347H has better creep resistance and lasting strength at high temperatures (above 500°C), and is suitable for long-term high temperature service environments (such as boilers and heat exchangers).

b. The stainless steel 347H valves produced by Freeman Valve have good anti-sensitization ability: Niobium (Nb) in the stainless steel 347H valves produced by Freeman Valve can reduce the precipitation of chromium carbide (Cr23C6) and reduce the risk of intergranular corrosion.

3.2 The stainless steel 347H valves produced by Freeman Valve have good weldability:

Similar to 347, the stainless steel 347H valves produced by Freeman Valve can maintain corrosion resistance without heat treatment after welding (but the heat input needs to be controlled to avoid heat affected zone problems).

3.3 Excellent corrosion resistance:

a. Freeman Valve's 347H stainless steel valves perform well in oxidizing media (such as nitric acid), better than 304H/321H.

b. Freeman Valve's 347H stainless steel valves have better resistance to chloride stress corrosion cracking (SCC) than 304H, but not as good as 316H.

4. The following issues should be noted when using 347H stainless steel valves:

4.1 The low-temperature toughness of 347H stainless steel valves is slightly lower. Due to the high carbon content, the low-temperature impact toughness may be slightly lower than that of low-carbon austenitic stainless steel (such as 304L).

4.2 Stainless steel 347H valves are not suitable for reducing environments. They have limited corrosion resistance in sulfur-containing or reducing acids (such as sulfuric acid), so materials should be selected with caution.

5. Classic application of stainless steel 347H in the chemical industry

Stainless steel 347H (UNS S34709) is widely used in high temperature, high pressure and highly corrosive environments in the chemical industry due to its excellent high temperature strength, anti-sensitization ability and corrosion resistance. The following are typical application scenarios:

5.1 Petrochemical industry, for example:

a. Freeman Valve's stainless steel 347/347H valves have been widely used in catalytic cracking units: the main advantages are resistance to high temperature (500-900℃) oil and gas corrosion, resistance to thermal fatigue and thermal shock (frequent start-up and shutdown conditions), and niobium stabilization to reduce the risk of post-welding sensitization;

b. Freeman Valve's stainless steel 347/347H valves have been widely used in ethylene cracking furnaces: the main advantages are resistance to high temperature (800-1100℃) hydrocarbon cracking environments, resistance to carburization and oxidation, and longer service life than 321H/304H;

c. Freeman Valve's stainless steel 347/347H valves have been widely used in hydroprocessing units: the main advantages are resistance to H₂S and high temperature hydrogen corrosion (better than 304H), and resistance to chloride stress corrosion cracking (SCC).

5.2 Fertilizer industry, for example:

a. Freeman Valve's stainless steel 347/347H valves have been widely used in nitric acid production equipment: the main advantage is excellent corrosion resistance in concentrated nitric acid (>65%), and can be used without heat treatment after welding;

b. Freeman Valve's stainless steel 347/347H valves have been widely used in urea synthesis equipment: the main advantage is resistance to high temperature and high pressure ammonium carbamate corrosion, and more resistant to high temperature creep than 316L.

5.3 Chemical processing field, for example:

a. Freeman Valve's stainless steel 347/347H valves have been widely used in sulfuric acid equipment and phosphoric acid equipment: the main advantage is good performance in medium concentration oxidizing acid (note: not suitable for reducing sulfuric acid environment, high molybdenum stainless steel such as 904L must be selected);

b. Freeman Valve's stainless steel 347/347H valves have been widely used in acetic acid production equipment: the main advantage is resistance to high temperature acetic acid corrosion (especially when containing halogen impurities).

5.4 Other chemical applications, such as:

a. Coal chemical industry, such as coal gasification furnace, synthesis gas pipeline: the main advantages are resistance to high temperature sulfur corrosion and thermal fatigue;

b. Chlor-alkali industry, such as high temperature chlorine treatment equipment: the main advantage is resistance to chloride ion stress corrosion (better than 304H);

c. Polymer production, such as polymerization reactor, hot oil system pipeline: the main advantage is long-term high temperature stability.

6. The core value of 347H valve in the chemical industry lies in:

a. High temperature stability (long-term use above 500℃);

b. Welding reliability (non-sensitization after welding);

c. Resistance to nitric acid/oxidizing medium corrosion.

7. Typical recommended scenarios for 347H valves:

a. High-temperature components of catalytic cracking unit (FCCU);

b. Ethylene cracking furnace tubes;

c. Nitric acid production equipment;

d. High-temperature and high-pressure heat exchangers.

8. Scenarios where 347H valves are not recommended:

a. Reducing sulfuric acid environment

b. High-concentration chloride and low-temperature environment (super austenitic stainless steel such as 254SMO is preferred)