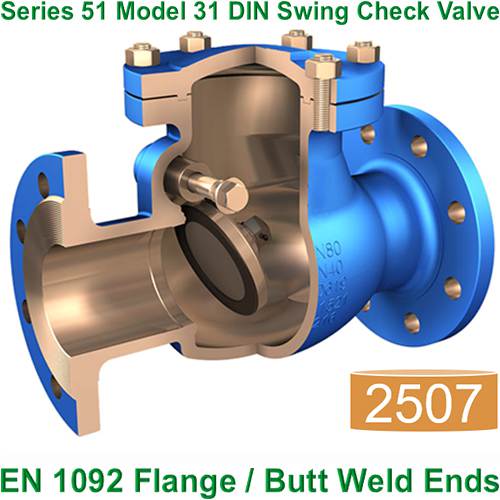

Advantages, Precautions, Selection, and Applications of Freeman Valve ASTM A995 5A DIN Swing Check Valve

ASTM A995 5A is a cast version of super duplex stainless steel (corresponding to 2507 forgings) defined by ASTM A995/A995M standards. It combines high strength with high corrosion resistance and is specifically designed for harsh corrosive environments such as those containing chlorine. Freeman Valve's DIN swing check valve in this series fully utilize the material's properties to meet the stringent requirements of various industries.

1. Core Advantages of Freeman Valve's ASTM A995 Gr. 5A DIN Swing Check Valve

Freeman Valve leverages its mature manufacturing processes to integrate the superior properties of ASTM A995 Gr. 5A material into its valve products. The core advantages are as follows:

1.1 Freeman Valve's ASTM A995 Gr. 5A DIN swing check valve possesses exceptional resistance to pitting and crevice corrosion: The PREN (pitting equivalent) of ASTM A995 Gr. 5A DIN swing check valve is >40, thanks to the high alloy ratio of 24-26% Cr, 4-5% Mo, and 0.2-0.3% N in the material. This allows for stable resistance to media with high chlorine concentrations exceeding 4% (such as seawater concentrate), and its corrosion resistance is far superior to 316L stainless steel and ordinary duplex stainless steel DIN swing check valve.

1.2 Freeman Valve's ASTM A995 Gr. 5A DIN swing check valve exhibit outstanding resistance to Cl⁻ stress corrosion cracking (SCC): Utilizing the material's inherent ferrite-austenite duplex structure and high nitrogen content, it effectively inhibits chloride ion-induced stress corrosion cracking, allowing for stable application in high-temperature, high-chlorine, and high-stress conditions, such as high-pressure sections of seawater desalination and flue gas desulfurization (FGD) slurry systems.

1.3 Freeman Valve's ASTM A995 Gr. 5A DIN swing check valve combines strength and corrosion resistance: ASTM A995 Gr. 5A DIN swing check valve has a yield strength ≥550MPa and a tensile strength ≥795MPa. This high strength allows for thinner valve body designs, reducing equipment structural weight and optimizing life-cycle costs, resulting in a superior overall cost-performance ratio compared to super austenitic steel DIN swing check valve such as 904L.

1.4 Freeman Valve's ASTM A995 Gr. 5A DIN swing check valve possesses excellent corrosion fatigue resistance: suitable for scenarios involving both dynamic loads and corrosive environments, such as DIN swing check valve for circulating pumps on offshore platforms, offering enhanced long-term stability and reducing equipment maintenance frequency.

2. Precautions for using ASTM A995 Gr. 4A DIN swing check valve

2.1 High-temperature limitations: At temperatures >315°C, ASTM A995 Gr. 4A DIN swing check valve are prone to intermetallic phase precipitation, leading to valve body embrittlement and decreased corrosion resistance. Therefore, they are not suitable for long-term high-temperature operation; the operating temperature range must be strictly controlled during selection.

3. Selection Guidelines for ASTM A995 Gr. 4A and ASTM A995 Gr. 5A DIN Swing Check Valve

Based on the material properties of both valve grades and actual operating conditions, Freeman Valve offers the following selection recommendations:

3.1 Use chloride ion concentration as the core selection criterion: When the Cl⁻ concentration in the medium is ≤2%, ASTM A995 Gr. 4A DIN swing check valve is preferred, as they meet general corrosion requirements and offer better cost-effectiveness;

3.2 When the Cl⁻ concentration is >2%, or when the operating conditions involve harsh conditions such as high temperature and high stress, ASTM A995 Gr. 5A DIN swing check valve are preferred;

3.3 For extreme corrosive conditions such as high-temperature concentrated hydrochloric acid, nickel-based alloy DIN swing check valve may be considered.

4. Key Application Areas of Freeman Valve's ASTM A995 Gr. 5A DIN Swing Check Valve

Leveraging the excellent corrosion resistance and high strength of its materials, Freeman Valve's ASTM A995 Gr. 5A DIN swing check valve has been widely used in several harsh and corrosive industries, specifically in the following scenarios:

4.1 Freeman Valve's ASTM A995 Gr. 5A DIN swing check valve is widely used in the oil and gas industry: for use in offshore platform equipment, including heat exchanger tubes, seawater treatment systems, fire/sprinkler systems, and other valve components, adaptable to the high-salt, high-humidity, and high-pressure corrosive environments of the sea;

4.2 Freeman Valve's ASTM A995 Gr. 5A DIN swing check valve is widely used in the chemical and petrochemical industries: used in reactors, heat exchangers, storage tanks, and pipelines, capable of withstanding various corrosive materials such as organic acids, inorganic acids, and chlorine-containing media, ensuring continuous and stable chemical production;

4.3 Freeman Valve's ASTM A995 Gr. 5A DIN swing check valve is widely used in the seawater desalination field: adaptable to the valve requirements of high-pressure seawater pipes, reverse osmosis unit components, evaporators, condensers, etc., resistant to high-chlorine seawater corrosion, and meeting the stringent requirements of seawater desalination processes;

4.4 Freeman Valve's ASTM A995 Gr. 5A DIN swing check valve is widely used in the power and environmental protection fields: mainly used in flue gas desulfurization (FGD) systems, wastewater treatment equipment, slurry circulation pumps/valve, etc., resisting chloride ion and acidic media corrosion, and contributing to environmentally compliant emissions;

4.5 Freeman Valve's ASTM A995 Gr. 5A DIN swing check valve is widely used in the marine engineering field: used in seawater cooling systems, subsea pipelines, and platform structural components, resistant to long-term seawater erosion and wave impact, ensuring the long-term reliability of marine engineering equipment.