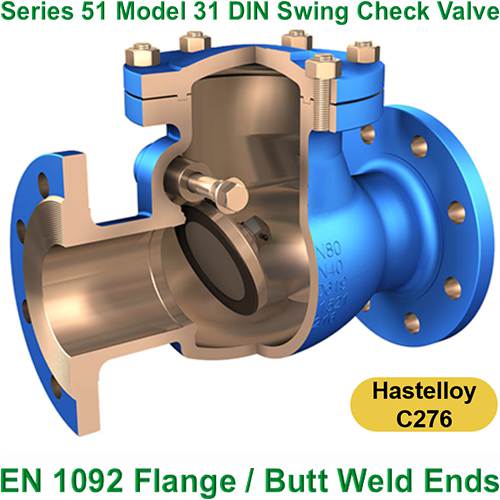

1. Freeman valve is a Hastelloy C276 DIN swing check valve manufacturer. Hastelloy C276 DIN swing check valve manufactured by Freeman Valve have the following significant advantages:

1.1 Excellent corrosion resistance

① It has strong resistance to both oxidizing and reducing media (such as hydrochloric acid, sulfuric acid, phosphoric acid, chlorine, chlorides, etc.).

② Resistant to pitting, crevice corrosion and stress corrosion cracking (SCC), especially in chlorine-containing environments.

1.2 Stable high temperature performance

① It still maintains corrosion resistance and mechanical strength at high temperatures (up to about 1093°C).

1.3 Good processing and weldability

① It can be formed by conventional processes (such as welding, cold working), and no heat treatment is required after welding.

The following matters need to be noted when using Hastelloy C276 DIN swing check valve:

① Hastelloy C276 DIN swing check valve is not suitable for strong oxidizing environments: for example, they may be corroded in strong oxidizing acids such as nitric acid and concentrated sulfuric acid.

2 Hastelloy C276 DIN swing check valve manufactured by Freeman valve have been widely used in the following five major fields:

2.1 Hastelloy C276 DIN swing check valve manufactured by Freeman valve have been widely used in the chemical and petrochemical fields. For example: reactors, heat exchangers, pipeline systems (especially involving hydrochloric acid, wet chlorine, and sulfur-containing environments).

2.2 Hastelloy C276 DIN swing check valve manufactured by Freeman valve have been widely used in environmental protection and flue gas desulfurization (FGD) fields. For example: chimney linings, washing towers and other acid-resistant parts.

2.3 Hastelloy C276 DIN swing check valve manufactured by Freeman valve have been widely used in the fields of ocean and seawater treatment. For example: seawater desalination equipment, submarine pipelines (resistant to chloride ion corrosion).

2.4 Hastelloy C276 DIN swing check valve manufactured by Freeman valve have been widely used in the pharmaceutical and food fields. For example: high-purity medium containers (corrosion-resistant and pollution-free).

2.5 The Hastelloy C276 DIN swing check valve manufactured by Freeman valve has been widely used in the energy industry. For example: nuclear power fuel assemblies, gas turbine components (high temperature corrosion resistance).

Summary

Hastelloy C276 DIN swing check valve is a benchmark for high-end corrosion-resistant alloy DIN swing check valve, suitable for harsh environments (such as high temperature, high chlorine, acidic media), but the cost and processing difficulty need to be weighed. Its irreplaceability is particularly prominent in the fields of chemical industry and environmental protection.

Hastelloy C276 DIN swing check valve performance in KOH (potassium hydroxide)

1. Freeman Valve's Hastelloy C276 DIN swing check valve has excellent performance in dealing with KOH (potassium hydroxide) corrosion:

1.1 Freeman Valve's Hastelloy C276 DIN swing check valve has excellent KOH (potassium hydroxide) corrosion resistance:

a. In KOH (potassium hydroxide) solution at room temperature or medium temperature (especially concentration ≤30%), Freeman Valve's Hastelloy C276 DIN swing check valve shows excellent KOH (potassium hydroxide) corrosion resistance, and its high chromium (Cr) and high molybdenum (Mo) content can effectively resist the erosion of KOH (potassium hydroxide).

b. Freeman Valve's Hastelloy C276 DIN swing check valve is less sensitive to stress corrosion cracking (SCC) caused by KOH (potassium hydroxide), which is better than ordinary stainless steel.

1.2 Hastelloy C276 DIN swing check valve produced by Freeman Valve have stability in high temperature KOH (potassium hydroxide) solution:

In high temperature (such as below 100°C) KOH (potassium hydroxide) environment, Hastelloy C276 DIN swing check valve produced by Freeman Valve can still maintain good corrosion resistance and are suitable for high temperature KOH (potassium hydroxide) solution treatment in chemical processes.

1.3 Hastelloy C276 DIN swing check valve produced by Freeman Valve have resistance to oxidation and reduction media in KOH (potassium hydroxide) solution:

The inertness of Hastelloy C276 DIN swing check valve produced by Freeman Valve makes their performance stable in the oxidation-reduction alternating environment of KOH (potassium hydroxide) solution (such as complex process media containing KOH).

1.4 Hastelloy C276 DIN swing check valve produced by Freeman Valve is resistant to local corrosion in KOH (potassium hydroxide) solutions:

Hastelloy C276 DIN swing check valve produced by Freeman Valve contain molybdenum (Mo) and tungsten (W), which enhance the ability to resist pitting and crevice corrosion of KOH (potassium hydroxide) and are suitable for KOH solutions containing impurities or Cl⁻ contamination.

2. When using Hastelloy C276 DIN swing check valve to deal with KOH (potassium hydroxide) corrosion, the following issues should be noted:

2.1 Limitations of Hastelloy C276 DIN swing check valve at high concentrations and high temperatures. In high-temperature (>120°C) and high-concentration (such as ≥50%) KOH (potassium hydroxide) solutions, the corrosion rate of Hastelloy C276 DIN swing check valve may increase significantly, and long-term use requires careful evaluation.

2.2 For pure KOH environments, some low-cost nickel-based alloy DIN swing check valve, such as nickel 200 DIN swing check valve, may be more cost-effective. The advantages of C276 DIN swing check valve is more reflected in complex environments containing impurities or mixed media.

3. Application recommendations for Hastelloy C276 DIN swing check valve:

3.1 Recommended scenarios: medium to low temperature, medium to low concentration KOH, or highly corrosive KOH (potassium hydroxide) solutions containing impurities such as Cl⁻ and sulfides.

3.2 Alternatives: If the environment is pure and the temperature/concentration of the KOH (potassium hydroxide) solution is low, nickel 200 DIN swing check valve can be considered to reduce costs.

3.3 Verification necessary: Before actual application, corrosion tests (such as ASTM G31) must be performed to confirm the performance under specific working conditions.

The corrosion performance of Hastelloy C276 DIN swing check valve in concentrated sulfuric acid (H₂SO₄ concentration ≥70%) is relatively complex, and its advantages and disadvantages can be summarized as follows:

Advantages

1.1 Hastelloy C276 DIN swing check valve produced by Freeman Valve have good tolerance in concentrated sulfuric acid (H₂SO₄ concentration ≥70%):

In sulfuric acid of medium concentration (about 50-80%) and medium temperature (≤50°C), C276 shows good corrosion resistance, especially when the sulfuric acid is pure and does not contain oxidizing impurities. Its high molybdenum (Mo≈16%) and chromium (Cr≈15%) content can form a stable passivation film.

1.2 The Hastelloy C276 DIN swing check valve produced by Freeman Valve is resistant to reducing acid corrosion in concentrated sulfuric acid (H₂SO₄ with a concentration of ≥70%):

In a reducing environment (such as low oxygen or no oxidant), the corrosion resistance of the Hastelloy C276 DIN swing check valve produced by Freeman Valve is better than that of ordinary stainless steel, because the Hastelloy C276 DIN swing check valve produced by Freeman Valve contains molybdenum, which can enhance the resistance to reducing acid.

1.3 The Hastelloy C276 DIN swing check valve produced by Freeman Valve is resistant to local corrosion in concentrated sulfuric acid (H₂SO₄ with a concentration of ≥70%):

The Hastelloy C276 DIN swing check valve produced by Freeman Valve has strong resistance to pitting and crevice corrosion that may be caused by concentrated sulfuric acid, thanks to the synergistic effect of the nickel matrix, molybdenum and chromium in the Hastelloy C276 DIN swing check valve produced by Freeman Valve.

Disadvantages

2.1 Limitations of Hastelloy C276 DIN swing check valve at high concentrations and high temperatures

In concentrated sulfuric acid with a concentration of ≥90% (especially at a high temperature of ≥100°C), the corrosion rate of Hastelloy C276 DIN swing check valve increases significantly and may exceed 0.5 mm/year (the upper limit acceptable to the industry). At this time, more corrosion-resistant materials such as high-silicon stainless steel (such as Alloy 20) or zirconium alloys need to be selected.

2.2 Sensitivity of Hastelloy C276 DIN swing check valve to oxidizing conditions

If concentrated sulfuric acid contains oxidizing impurities (such as Fe³⁺, Cu²⁺ or dissolved oxygen), the passivation film of Hastelloy C276 DIN swing check valve may be destroyed, resulting in accelerated corrosion. At this time, alloys containing tantalum (Ta) (such as C22) or tantalum materials are better.

3 Applicable recommendations

3.1 Recommended working conditions: sulfuric acid with medium and low concentrations (≤80%), low temperatures (≤50°C) and no oxidizing impurities.

3.2 Avoid working conditions: fuming sulfuric acid (containing free SO₃), high temperature (≥100°C) or highly oxidizing environment.

3.3 Alternative materials for Hastelloy C276 DIN swing check valve: Hastelloy B3 DIN swing check valve (pure reducing acid), zirconium alloy DIN swing check valve or high silicon material DIN swing check valve can be selected under extreme conditions.

4 Corrosion rate examples (data reference):

80% H₂SO₄, 30°C: <0.1 mm/year (C276 performs well)

98% H₂SO₄, 80°C: >1 mm/year (C276 is not recommended)

Therefore, the selection of Hastelloy C276 DIN swing check valve needs to be verified by experiments or corrosion databases (such as NACE or manufacturer manuals) based on specific working conditions (temperature, impurities, flow rate, etc.).