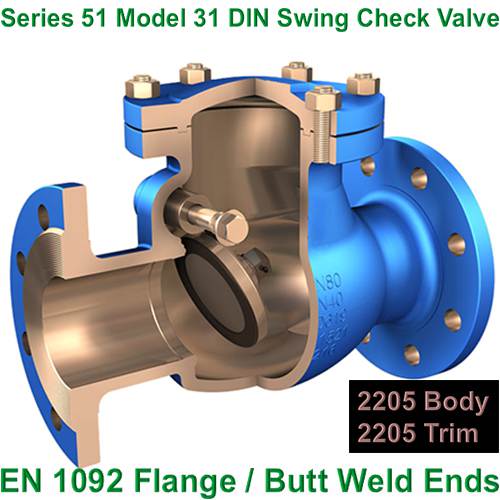

Performance, Precautions, and Differences from A182 F51 of Freeman Valve's ASTM A995 Gr. 4A DIN check valve

ASTM A995 Gr. 4A (formerly CD3MN), as a cast version of 2205 duplex stainless steel, is an ideal DIN check valve material for chloride-containing environments due to its excellent resistance to chloride ion corrosion. The following focuses on the core advantages, usage precautions, differences from the forged version (ASTM A182 F51), and its shortcomings of this DIN check valve model manufactured by Freeman Valve.

1. Core Advantages of Freeman Valve's ASTM A995 Gr. 4A DIN check valve in Resisting Chloride Ion Corrosion

1.1 Excellent Resistance to Chloride Ion Stress Corrosion Cracking (SCC)

This is the most crucial advantage of this DIN check valve model and the key reason why it replaces the traditional CF3M DIN check valve. From a mechanistic perspective, ASTM A995 Gr. 4A employs a ferrite (F) + austenite (A) dual-phase microstructure, completely breaking the SCC sensitivity mechanism of pure austenitic stainless steel under the coupled effects of chloride ions and tensile stress. The ferrite phase effectively inhibits crack propagation, significantly improving the DIN check valve's SCC threshold.

In practical applications, this DIN check valve exhibits far superior corrosion resistance to 304 and 316L austenitic stainless-steel castings in typical SCC environments such as seawater, brine, and chlorinated process media. It can operate stably for extended periods under conditions where traditional austenitic stainless-steel DIN check valve frequently fail, greatly improving equipment reliability.

1.2 Excellent Resistance to Pitting and Crevice Corrosion

This advantage stems from its well-designed alloy composition: ASTM A995 Gr. 4A contains approximately 22% chromium (Cr), 3% molybdenum (Mo), and 0.10–0.30% nitrogen (N), achieving a pitting resistance equivalent (PREN) of 32–38, comparable to forged 2205 (UNS S32205) duplex steel and significantly higher than 316L castings (PREN≈25).

The synergistic effect of Mo and N is particularly crucial, giving it extremely strong resistance to pitting and crevice corrosion in neutral to weakly acidic media containing chloride ions (such as seawater and chloride solutions). It is especially suitable for complex casting structures with gaps, easily deposited media, and localized stagnation, such as DIN check valve internal flow channels and flange sealing surfaces, reducing the risk of localized corrosion failure at its source.

1.3 Excellent Resistance to Uniform Corrosion

In neutral, weakly alkaline, and weakly acidic environments containing chloride ions, the high Cr content in ASTM A995 Gr. 4A DIN check valve forms a stable passivation film with an extremely low overall uniform corrosion rate, far superior to ordinary carbon steel and low-alloy cast iron DIN check valve. This effectively resists the overall erosion of the DIN check valve body by chloride ions, extending the DIN check valve's service life.

2. Precautions for Using ASTM A995 Gr. 4A DIN check valve

2.1 Temperature Limitations

The recommended long-term operating temperature for this DIN check valve is ≤300℃. Exceeding this temperature will significantly reduce the stability of its duplex structure, accelerate the precipitation of intermetallic phases, and significantly deteriorate its resistance to chloride ion corrosion. Especially under the combined conditions of "high temperature + high chloride," its corrosion resistance is far inferior to that of super duplex steel castings (such as ASTM A995 5A/6A) or nickel-based alloy castings, requiring material upgrades based on the specific operating conditions.

2.2 Concentration/Pressure Limitations

Use in extreme corrosive conditions should be avoided: Environments with extremely high concentrations of chloride ions, high temperature and pressure, or strong acidic chlorides (such as high-temperature concentrated hydrochloric acid, high-chlorine and high-pressure oil and gas) require careful consideration. ASTM A995 Gr. 4A DIN check valve have insufficient resistance to pitting corrosion and SCC, making them prone to rapid corrosion failure. Appropriate selection based on operating conditions is necessary.

3. Core Differences Between ASTM A995 Gr. 4A and ASTM A182 F51 DIN check valve

Both belong to the 2205 duplex stainless steel system. The core difference lies only in the manufacturing process and corresponding standards, as follows:

• ASTM A995 Gr. 4A: Follows the ASTM A995 standard and is a cast version of 2205 duplex stainless steel, primarily used for DIN check valve components with complex structures (such as DIN check valve bodies and covers).

• ASTM A182 F51: Follows the ASTM A182 standard and is a forged version of 2205 duplex stainless steel, emphasizing high strength and consistent performance. It is often used for DIN check valve forgings with higher mechanical performance requirements.

4. Shortcomings of ASTM A995 Gr. 4A (Cast Version) Compared to ASTM A182 F51 (Forged Version)

4.1 Poor Performance Consistency and Microstructure Uniformity

The casting process has inherent limitations. During solidification, ASTM A995 Gr. 4A DIN check valve are prone to defects such as component segregation, coarse grains, and localized porosity/venting. This leads to significant fluctuations in mechanical properties and corrosion resistance in different parts of the same batch or even the same DIN check valve. Performance stability is far lower than that of the forged version of ASTM A182 F51 DIN check valve. This shortcoming needs to be compensated for through rigorous heat treatment processes and non-destructive testing methods. 4.2 Slightly Inferior Low-Temperature Toughness and Plasticity

The elongation after fracture requirement for ASTM A995 Gr. 4A DIN check valve is ≥20%, lower than that of forged ASTM A182 F51 DIN check valve (≥25%). Its low-temperature toughness (especially for thick-section DIN check valve) is more significantly affected by casting defects. If used in low-temperature conditions <-20℃, additional impact toughness verification is required, and the applicable low-temperature range is narrower than the forged version.

4.3 High Risk of Casting Defects and Strict Inspection Requirements

During the production process, this DIN check valve is prone to casting defects such as shrinkage cavities, porosity, slag inclusions, and cold shuts. Since the DIN check valve is a pressure-bearing component, mandatory non-destructive testing (UT), MT (magnetic particle testing), and PT (penetrating electrode testing) is required. The cost of defect detection and repair is high, and the overall failure rate is slightly higher than that of ASTM A182 F51 forged DIN check valve.