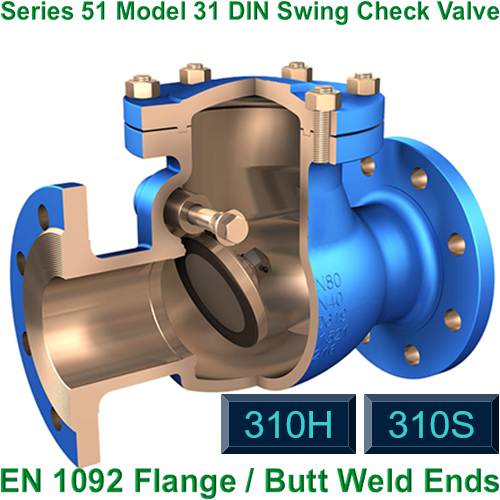

Stainless Steel 310H Check Valve (UNS S31009 Check Valve)

Freeman valve is a manufacturer of stainless steel 310H check valve. Stainless steel 310H check valve (UNS S31009 check valve) is high chromium-nickel austenitic stainless steel check valve. Due to their excellent high temperature resistance, oxidation resistance and corrosion resistance, stainless steel 310H check valve is widely used in high temperature and corrosive environments. Stainless steel 310H check valve manufactured by Freeman valve have been widely used in the following eight fields:

1. Stainless steel 310H check valve manufactured by Freeman valve have been widely used in high temperature heat treatment. The main application scenarios are: furnace parts, radiation tubes, muffle tanks, heat treatment brackets, burners, etc.

The stainless steel 310H check valve manufactured by Freeman valve have high chromium (24-26%) and nickel (19-22%) contents, which enable them to maintain excellent oxidation resistance and carburization resistance at continuous high temperatures (up to 1150°C). Therefore, the stainless steel 310H check valve manufactured by Freeman valve have the following obvious advantages in the field of high-temperature heat treatment:

① Protect steel from oxidation during annealing (such as continuous annealing furnace).

② Resist carbon penetration and extend component life (such as carburizing furnace).

③ Tolerate high-temperature reducing atmosphere in powder metallurgy (such as sintering equipment).

2. The stainless steel 310H check valve manufactured by Freeman valve have been widely used in the fields of petrochemicals and refining. The main application scenarios are: catalytic cracking units, reforming furnace tubes, heat exchangers, sulfur recovery units, etc.

The stainless steel 310H check valve manufactured by Freeman valve can resist sulfidation, oxidation and carburization. Therefore, the stainless steel 310H check valve manufactured by Freeman valve have the following obvious advantages in the field of petrochemicals and refining:

① Resist coking and thermal fatigue in high-temperature hydrocarbon cracking environments (such as cracking furnace tubes).

② Tolerate hydrogen sulfide and sulfur dioxide corrosion (such as sulfur recovery units).

③ Strong stability in high-temperature steam environments (such as ethylene production).

3. Freeman valve's 310H stainless steel check valve have been widely used in the power and energy fields. The main application scenarios are: boiler components, superheater tubes, gas turbine combustion chambers, biomass power generation equipment, etc. Freeman valve's 310H stainless steel check valve have the following obvious advantages in the power and energy fields:

① Resistant to coal ash corrosion (for example, used in high-temperature flue gas areas (such as superheater hangers), coal-fired boilers/gas boilers).

② Resistant to chloride and alkali metal corrosion (such as biomass combustion).

③ High-temperature pipelines of some auxiliary systems (such as nuclear power).

4. Freeman valve's 310H stainless steel check valve have been widely used in the chemical processing field. The main application scenarios are: reactors, distillation towers, pipelines, pickling equipment, etc. Freeman valve's 310H stainless steel check valve have the following obvious advantages in the chemical processing field:

① Perform well in strong acid (such as nitric acid, organic acid) and mixed acid environments (but note the limitations: not suitable for reducing acids (such as hydrochloric acid) or halogen environments).

② Heating coils and phthalic anhydride reactor linings used in nitric acid production (typical uses).

5. Freeman valve's 310H stainless steel check valve have been widely used in the glass and ceramic manufacturing industry. The main application scenarios are: glass furnace components, ceramic sintering brackets, molds, etc. Freeman valve's 310H stainless steel check valve have the following obvious advantages in the glass and ceramic manufacturing industry:

① High temperature oxidation resistance (glass fiber production: used for support structures around platinum-rhodium alloy leak plates).

② Ceramic sintering (as a kiln material, it resists repeated thermal cycles and has a low thermal expansion coefficient).

6. Freeman valve's 310H stainless steel check valve have been widely used in the aerospace industry. The main application scenarios are: engine exhaust components, afterburner linings, etc. Freeman valve's 310H stainless steel check valve have the following obvious advantages in the aerospace industry:

① It can be used as a secondary material in intermittent ultra-high temperatures to supplement nickel-based alloys and reduce costs (such as jet engine tail nozzles).

7. The stainless steel 310H check valve manufactured by Freeman valve have been widely used in the field of environmental protection and waste treatment. The main application scenarios are: garbage incinerators, hazardous waste treatment equipment, etc. The stainless steel 310H check valve manufactured by Freeman valve have the following obvious advantages in the field of environmental protection and waste treatment:

① Resistant to dioxin, chloride and heavy metal vapor corrosion (resistant to acidic gas (SO₂, HCl) and fly ash erosion).

② Anti-corrosion in high-temperature sections (such as flue gas ducts).

8. The stainless steel 310H check valve manufactured by Freeman valve have been widely used in the field of food processing. The main application scenarios are: high-temperature baking equipment, fermentation tank heating elements, etc. The stainless steel 310H check valve manufactured by Freeman valve have the following obvious advantages in the field of food processing:

① Good performance in the field of pollution-free and resistant to food acidic steam (such as high-temperature drying pipelines).

The following matters need to be noted when using 310H check valve:

① 310H special welding materials (such as ER310H) are required to avoid intergranular corrosion.

② The cost is higher than 304/316, and it is usually used to replace nickel-based alloys only in extremely high temperature or corrosive environments.

③ Because 310H does not contain molybdenum, it may not be as good as 316L in chloride environments.

In summary, the core advantage of 310H check valve lies in high temperature stability, and its application selection needs to balance temperature, medium composition and cost.

Stainless Steel 310S Check Valve (UNS S31008 Check Valve)

Freeman valve is a stainless steel 310S check valve manufacturer. Stainless steel 310S check valve (UNS S31008) is a high alloy austenitic stainless steel check valve. Due to its excellent high temperature resistance, oxidation resistance and corrosion resistance, it is widely used in high temperature and corrosive environments. Stainless steel 310S check valve manufactured by Freeman valve have been widely used in the following eight fields:

1. Stainless steel 310S check valve manufactured by Freeman valve have been widely used in high temperature heat treatment. Classic application areas include:

① Furnace parts: such as radiation tubes, muffle tanks, furnace rollers, etc., which are exposed to high temperature environments for a long time.

② Heat treatment fixtures: used to fix workpieces in quenching, annealing and other processes to avoid failure due to thermal deformation.

③ Burner parts: such as combustion chamber linings, which can withstand high temperature oxidation of gas.

Advantages of stainless steel 310S check valve in high temperature heat treatment: they can maintain excellent oxidation resistance and strength at high temperatures (up to 1150°C); high chromium (25%) and nickel (20%) content forms a stable chromium oxide protective layer to prevent further oxidation.

2. Stainless steel 310S check valve manufactured by Freeman valve have been widely used in the fields of petrochemical and refining equipment. Classic application areas include:

① Used in corrosive media and high temperature and high pressure environments:

② Cracking furnace tubes: Tolerate high temperature hydrocarbon corrosion in ethylene cracking units.

③ Catalytic cracking units: such as reactor linings and cyclone separators, resist hydrogen sulfide and acid gas corrosion.

④ Heat exchangers: used for heat exchange of high temperature corrosive fluids (such as sulfuric acid and nitric acid).

Advantages of stainless steel 310S check valve in the fields of petrochemical and refining equipment: Resistant to sulfide and chloride stress corrosion cracking, better than ordinary 304/316 stainless steel.

3. Freeman valve's 310S stainless steel check valve have been widely used in the power and energy fields. Classic application areas include:

① Boiler components: such as superheater tubes and combustion chamber liners, which can withstand high-temperature flue gas corrosion from coal or gas.

② Nuclear power equipment: some non-core auxiliary system components that need to withstand high temperatures.

③ Waste incinerators: Resist chlorine and acid gas corrosion produced by incineration.

Advantages of 310S stainless steel check valve in the power and energy industry: strong stability in a cyclic redox environment.

4. Freeman valve's 310S stainless steel check valve have been widely used in the glass and ceramic manufacturing fields. Classic application areas include:

① Glass melting furnace: used for crucibles, molds, and conveyor rollers, which can withstand erosion by molten glass (above 1400°C).

② Ceramic sintering furnace: kiln cars, brackets, etc. need to withstand repeated high-temperature heating-cooling cycles.

Advantages of stainless steel 310S check valve in the field of glass and ceramic manufacturing: low pollution (avoid contamination of glass/ceramic products), not easy to deform at high temperatures.

5. Stainless steel 310S check valve manufactured by Freeman valve have been widely used in the field of chemical processing equipment. Classic application areas include:

Detailed description:

① Reactor and pipeline: handle strong acid (such as concentrated nitric acid), strong alkali or mixed chemical media.

② Catalyst carrier: withstand high temperature corrosion in fertilizer or petrochemical catalytic reactions.

Advantages of stainless steel 310S check valve in the field of chemical processing equipment: strong resistance to intergranular corrosion and pitting corrosion.

6. Stainless steel 310S check valve manufactured by Freeman valve have been widely used in the food and pharmaceutical industries. Classic application areas include:

① High temperature sterilization equipment: withstand chemical corrosion of high pressure steam (>120℃) and frequent cleaning.

② Drying equipment: such as the high temperature area of the spray drying tower.

Advantages of stainless steel 310S check valve in the food and pharmaceutical industries: meet food-grade hygiene standards (surface polishing required), no risk of metal ion migration.

7. Stainless steel 310S check valve manufactured by Freeman valve have been widely used in environmental protection and waste gas treatment. Classic application areas include:

① Flue gas desulfurization (FGD) system: absorption tower internal components, resist chloride ion corrosion in wet desulfurization.

② Waste gas incineration device: high-temperature part when treating VOCs or acidic waste gas.

Advantages of stainless steel 310S check valve in environmental protection and waste gas treatment: Stainless steel 310S check valve is more suitable for high chloride ion environments.

8. Stainless steel 310S check valve manufactured by Freeman valve have been widely used in aerospace and special fields. Classic application areas include:

① Rocket engine components: such as nozzle bushings, short-term tolerance to extremely high temperatures.

② High-temperature sensor sheath: protect thermocouples from long-term operation in extreme environments.

Advantages of stainless steel 310S check valve in aerospace and special fields: low thermal expansion coefficient, reduced thermal fatigue.

The following points should be noted when using 310S check valve:

① Cost considerations: 310S check valve is expensive due to their high nickel content and are usually only used to replace ordinary stainless steel in extreme environments.

② Processing difficulty: The high hardness of 310S check valve requires special tools, and the interlayer temperature must be controlled during welding to avoid carbide precipitation.

In summary, the core value of 310S check valve lies in their dual tolerance to "high temperature + corrosion", making them an irreplaceable material choice in the above fields.

310H Check Valve vs 310S Check Valve

Stainless steel 310H check valve (UNS S31009 check valve) and stainless steel 310S check valve (UNS S31008 check valve) belong to the austenitic heat-resistant stainless steel series. The main difference lies in the carbon content and high temperature performance, so the application areas are different. The following are its main application areas and detailed descriptions:

1. Differences in check valve composition and performance between stainless steel 310H check valve (UNS S31009 check valve) and stainless steel 310S (UNS S31008 check valve)

Advantages of stainless steel 310H check valve (UNS S31009 check valve):

① Carbon content of stainless steel 310H check valve: 0.04–0.10% (enhanced high temperature strength);

② High temperature performance of stainless steel 310H check valve: strong creep resistance and high lasting strength;

③ Weldability of stainless steel 310H check valve: be cautious (high carbon can easily lead to sensitization);

Advantages of stainless steel 310S check valve (UNS S31008 check valve):

① Carbon content of stainless steel 310S check valve: ≤0.08% (better corrosion resistance);

② High temperature performance of stainless steel 310S check valve: good oxidation resistance, but low high temperature strength;

③ Weldability of stainless steel 310S check valve: Easier to weld (low carbon reduces carbide precipitation)

2. Comparison of application fields of stainless steel 310H check valve (UNS S31009 check valve) and stainless steel 310S check valve (UNS S31008 check valve)

Typical application scenarios of stainless steel 310H check valve (UNS S31009 check valve) is high-temperature pressure-bearing parts, such as:

① Petrochemical industry: cracking furnace tubes, converter parts (need to withstand high temperature + stress).

② Power industry: boiler burners, superheater tubes (operating temperature can reach 1100°C).

③ Heat treatment equipment: high-temperature furnace rollers, muffle tanks (need to resist creep).

So the key requirement for selecting stainless steel 310H check valve should be: maintaining structural strength in long-term high temperature environments (such as >800°C).

The typical application scenarios of stainless steel 310S check valve (UNS S31008 check valve) is oxidation-resistant but low-stress environments, such as:

① Food industry: oven liner, baking mold (resistant to high temperature oxidation, no need for high mechanical strength).

② Chemical containers: corrosive medium storage tanks (low carbon reduces the risk of intergranular corrosion).

③ General heat-resistant parts: heat exchanger pipes, flue linings (temperature ≤1000°C).

Therefore, the key requirements for selecting stainless steel 310S check valve should be: corrosion resistance, easy molding or welding, and low high-temperature stress scenarios.

3. Stainless steel 310H check valve (UNS S31009 check valve) and stainless steel 310S check valve (UNS S31008 check valve) selection recommendations:

① Choose stainless steel 310H check valve: when the equipment needs to withstand mechanical loads for a long time at high temperatures (such as furnace tubes, supports).

② Choose stainless steel 310S check valve: when oxidation/corrosion resistance is the main factor, or welding processing is required (such as containers, non-pressure-bearing parts).

Note: Under extremely high temperatures (>1000°C), the oxidation resistance of stainless steel 310H check valve and stainless steel 310S check valve is similar, but the strength advantage of 310H is more significant.

Summary

The difference between stainless steel 310H check valve and stainless steel 310S check valve is essentially the choice of "strength first" and "corrosion resistance/process first", which needs to be determined according to the temperature, stress and processing requirements of specific working conditions.